Ceramic Aroma Diffuser Manufacturer | From Craft to Custom Branding

- October 8, 2025

Table of Contents

Introduction

Modern businesses seeking premium ambiance and distinctive branding rely on ceramic diffusers to create memorable customer experiences. Understanding the complete manufacturing journey from raw clay to finished, custom-branded products helps businesses make informed decisions when selecting wholesale ceramic diffuser partners. AromaLeap’s comprehensive manufacturing process showcases how traditional ceramic craftsmanship meets modern commercial requirements, delivering products that enhance both functionality and brand identity. This transparency into our production methods demonstrates our commitment to quality control, customization capabilities, and reliable wholesale partnerships for businesses requiring bulk ceramic diffuser solutions

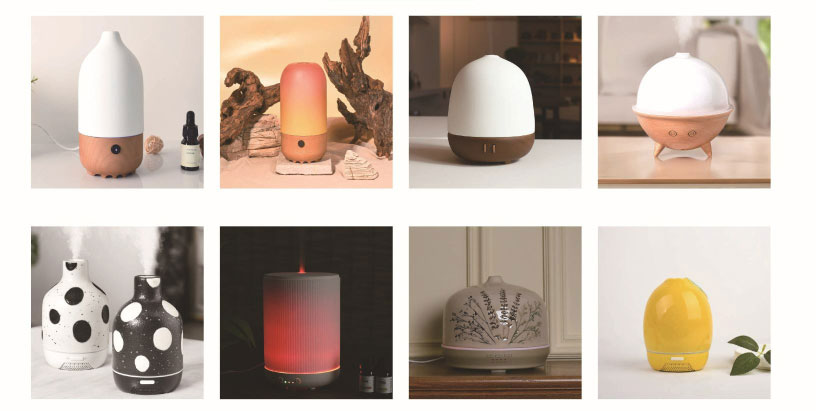

Raw Materials & Clay Preparation

The foundation of every premium ceramic diffuser begins with careful selection and preparation of raw materials that determine both durability and aesthetic appeal. High-grade ceramic materials including kaolin, feldspar, and silica, which form the base composition for different ceramic types ranging from terra cotta to porcelain. Each material serves a specific purpose: kaolin provides plasticity and workability, feldspar acts as a flux to lower firing temperatures, and silica controls shrinkage and enhances structural integrity.

.Before shaping begins, each batch undergoes fine milling and filtration to achieve optimal particle size, ensuring a smooth finish and consistent performance in every diffuser. The clay is hydrated, mixed, and aged under controlled conditions to achieve an even texture and pliability. Rigorous quality tests verify moisture content, density, and plasticity — key factors that determine how well the clay will shape and fire. Our technicians continuously monitor these parameters to maintain consistency across mass production.

Ceramic Forming & Shaping Techniques

Once the clay is prepared, it transitions into the forming stage — where creativity and precision unite. At AromaLeap, we employ a range of shaping techniques tailored to different diffuser designs and production scales:

Slip Casting: Ideal for smooth, intricate shapes and consistent mass production. Liquid clay (slip) is poured into custom molds that define the diffuser’s silhouette.

Injection Molding: Used for uniform, high-volume production where precision and repeatability are critical.

Wheel Throwing: Reserved for artisan collections or small runs, emphasizing handcrafted beauty and uniqueness.

Custom Mold Creation: Enables fully personalized designs, including brand logos, patterns, and embossed surfaces that reflect each client’s aesthetic identity.

Every shaping technique is guided by strict dimensional standards to ensure a perfect fit with electronic components later in the process. This phase bridges artistry and engineering, giving each diffuser its recognizable structure before moving on to drying and firing

Drying & Bisque Firing Process

After shaping, each ceramic diffuser enters a meticulously controlled drying phase, crucial for preventing cracks and warping. These diffusers are placed in climate-regulated environments, allowing moisture to evaporate gradually and evenly from the clay bodies. Slow drying preserves the integrity of delicate designs and ensures dimensional accuracy for later assembly.

Once sufficiently dried, the diffusers undergo bisque firing in kilns at temperatures between 800°C and 1000°C. This initial firing transforms the raw clay into a porous, durable structure ready for glazing and decoration. The bisque-fired bodies pass through quality inspections to confirm strength, color consistency, and surface smoothness before custom branding and finishing.

Custom Logo Application & Branding Crafts

AromaLeap offers diverse and advanced logo application methods to elevate brand identity for bulk diffuser orders:

Laser Engraving: Yields highly precise, permanent designs that resist wear and create a crisp, professional appearance.

Silk Printing (Screen Printing): Silk printing, also known as screen printing, involves pressing ink through a fine mesh stencil directly onto the ceramic surface or onto a transfer paper. This method works beautifully for single or multi-color logos, especially on flat or gently curved sections of the diffuser. The ink is later fused in a kiln during the final firing, ensuring long-lasting color and sharp contours on the logo.

Hand-Painting & Decals: Artists hand-paint custom designs, or use specially printed decals, for brands seeking an artisanal or intricate look.

Glazing Techniques: Custom color glazes applied before main firing can highlight logo areas or create distinctive finishes.

Electroplating: Adds metallic effects for a premium, tactile brand accent.

Each branding technique is tested for durability and colorfastness. Clients can combine methods to achieve complex, bespoke branding effects that stand out on retail shelves and in premium gift sets

Glazing & Final Firing Excellence

With logo decoration complete, each diffuser receives a specialized ceramic glaze—a coating that ensures waterproofing, stain resistance, and aesthetic brilliance. Glazes are applied using techniques such as spraying or dipping, carefully controlling thickness and uniformity.

The glazed diffusers undergo a main firing at temperatures between 1200°C and 1300°C, which vitrifies the glaze and strengthens the ceramic body. This final firing produces a lustrous, durable finish that protects both the vessel and branding elements. Every finished piece is inspected for color accuracy, surface smoothness, and structural resilience, meeting premium standards for wholesale distribution

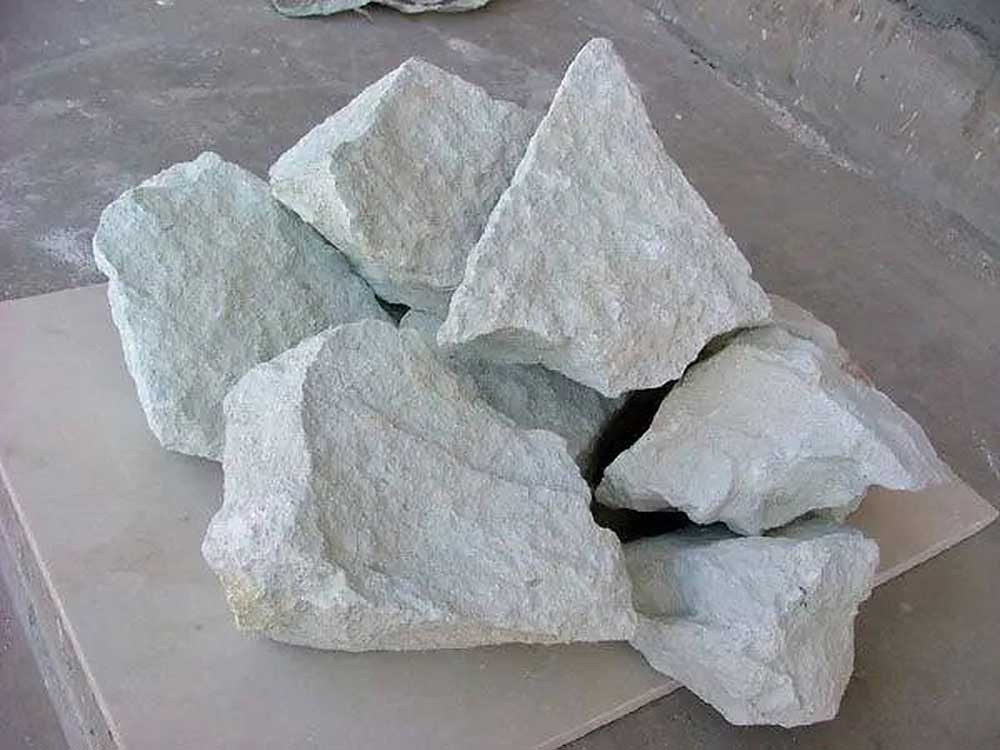

Premium Ceramic Cover Crafts & Techniques

Beyond the standard ceramic body, AromaLeap specializes in creating distinctive ceramic covers that serve as the visual centerpiece of each diffuser. These covers combine functional protection with artistic expression, offering brands extensive customization options for bulk orders. From cost-effective solutions to luxury finishes, our comprehensive range of ceramic crafts ensures every client finds the perfect match for their market positioning and aesthetic vision.

| Seris | Ceramic Craft Type | Complexity Range | Key Features |

|---|---|---|---|

| 1 | Medium-Temperature Ceramic | Intermediate | Durable, cost-effective, suitable for bulk production |

| 2 | High-Temperature Translucent Ceramic | Advanced | Premium appearance, light transmission properties, luxury feel |

| 3 | Rubber-Painted Ceramic (Silky Touch) | Expert | Unique tactile experience, anti-slip properties, modern aesthetics |

| 4 | Glazed Ceramic | Basic to Intermediate | Waterproof finish, easy cleaning, vibrant colors available |

| 5 | Sand-Coated Matte Ceramic | Intermediate | Soft matte texture, fingerprint resistant, contemporary look |

| 6 | Laser-Engraved Ceramic | Expert | Precise custom branding, permanent marking, high contrast |

| 7 | Kiln-Transformation Glaze | Expert | Unique color variations, no two pieces identical, premium appeal |

| 8 | Mibian Glaze | Expert | Smooth premium finish, sophisticated appearance, commercial grade |

| 9 | Pattern Design Ceramic (Striped/Polka Dot) | Intermediate | Eye-catching designs, brand differentiation, decorative appeal |

| 10 | Tricolor/Four-Color Ceramic | Advanced | Vibrant multi-color effects, artistic appearance, premium branding |

| 11 | Animal/Plant Form Ceramic | Basic to Intermediate | Themed designs, market appeal, gift-ready packaging |

| 12 | Wood-Ceramic Combination | Advanced | Natural warmth, eco-friendly appeal, mixed material aesthetics |

| 13 | Bamboo-Ceramic Combination | Advanced | Sustainable materials, lightweight, natural texture combination |

| 14 | Hand-Painted Ceramic | Advanced | Artistic customization, unlimited color options, handcrafted appeal |

| 15 | Ceramic Decal Application | Intermediate | Full-color logo reproduction, photo-quality printing, brand consistency |

| 16 | Electroplated Ceramic | Expert | Metallic surface finish, luxury appearance, corrosion resistance |

| 17 | Textured Surface Ceramic | Intermediate to Advanced | 3D surface effects, tactile experience, visual depth enhancement |

| 18 | Crackle Glaze Ceramic | Advanced | Traditional ceramic art, vintage appeal, artistic value |

| 19 | Metallic Finish Ceramic | Advanced | Premium metallic accents, luxury branding, high-end market appeal |

| 20 | Gradient Color Ceramic | Advanced | Smooth color transitions, modern aesthetics, Instagram-worthy design |

Quality Inspection & Testing Standards

Strict quality control is central to AromaLeap’s reputation for dependability and excellence. Every ceramic diffuser undergoes a sequence of visual and mechanical inspections, where each piece is checked for surface flaws, glaze consistency, and color uniformity. Specialized equipment is used to confirm dimensional accuracy, water-resistance, and overall structural integrity.

Beyond visual checks, diffusers are subjected to functional tests—including stress tests and leak checks—to ensure they meet bulk order requirements and international manufacturing standards. AromaLeap follows strict industry certifications to guarantee every product is safe, reliable, and ready for commercial use

Assembly & Component Integration

With high-precision ceramics complete, the process moves to technical assembly. Electronic components such as printed circuit boards (PCBs), fan units, and essential oil carriers are installed within the diffuser body. Each part is fitted and tested for alignment and secure integration—ensuring seamless operation.

Compatibility tests are conducted with various essential oils, verifying that the ceramic vessel can withstand extended use without degrading. Final assembly includes installation of power adapters, buttons, and safety features, preparing the diffusers for packaging and shipment

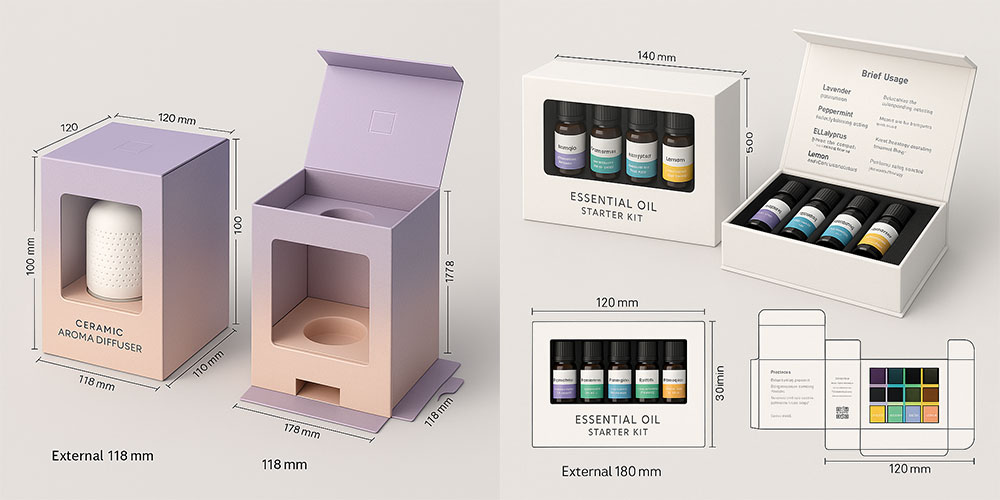

Packaging Solutions & Wholesale Logistics

AromaLeap offers eco-friendly packaging options tailored for both retail and bulk distribution. Custom gift boxes, recyclable cartons, and protective inserts ensure products reach clients undamaged. Branding elements—like logo-printed boxes and marketing collateral—can be added for a personalized presentation.

For wholesale orders, robust bulk shipping solutions simplify logistics, with coordinated shipping schedules and international freight services available. Packaging designs are optimized for efficient storing and handling, delivering both environmental responsibility and cost-effectiveness for business buyers

Conclusion

AromaLeap stands at the forefront of ceramic diffuser manufacturing, combining advanced processes, artisanal craftsmanship, and strict quality control for every bulk order. With a full spectrum of ceramic cover techniques—ranging from cost-effective and durable to luxurious and bespoke—business buyers receive diffuser solutions that meet the highest standards of beauty, functionality, and brand identity. Whether seeking rapid mass production or custom-branded, limited-edition runs, AromaLeap’s expert team provides guided support from material selection through final assembly and logistics.